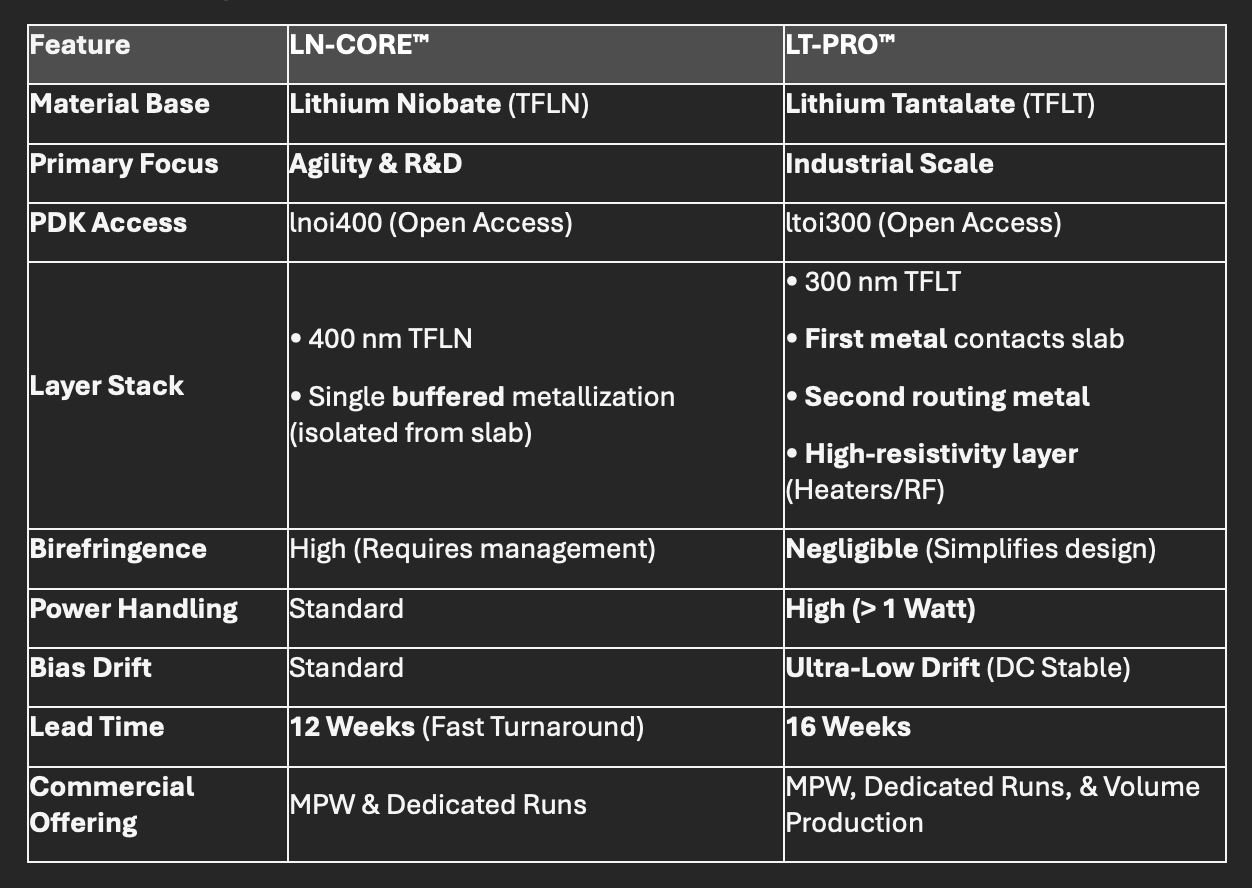

While both Lithium Niobate (LN) and Lithium Tantalate (LT) share similar crystal structures and excellent electro-optic properties, they serve different strategic needs. We have optimized our TFLX™ technology into two distinct platforms to leverage the specific strengths of each material.

Optimized for Speed & Agility. The traditional choice for maximum electro-optic efficiency.

Optimized for Scale & Stability. The industrial choice for robustness and volume manufacturing.

The Lithium Tantalate Advantage (LT-PRO)

Lithium Tantalate is the “sister material” to Lithium Niobate. It matches LN in bandwidth but offers superior optical stability and manufacturability. Previously, LT was difficult to process for photonics, but our TFLX™ etching technology has unlocked it as a premier material for industrial modulators.

Unlike Niobate, Lithium Tantalate exhibits negligible birefringence. This optical isotropy is a game-changer for circuit design, enabling high-density integration and complex passive components without complex polarization management.

The LT-PRO platform is more resistant to the “optical damage” (photorefractive effect) that limits standard TFLN. This allows our modulators to handle optical powers exceeding 1W without signal degradation.

The low photorefractive effect also translates to superior temporal stability. LT-PRO modulators exhibit ultra-low bias drift, maintaining performance over long-term operation.

Lithium tantalate modulators operate efficiently in the 450–900 nm range making it a great platform for trapped ion quantum computers and integrated high-precision atomic clocks.

Lithium Tantalate is the standard material for the global 5G RF filter industry. By leveraging this mature supply chain, Luxtelligence has secured a path to 6-inch and 8-inch volume production. Through our foundry partnerships, LT-PROcan scale to volumes exceeding 10,000 wafers/month, bridging the gap between niche photonics and mass-market consumer electronics.